Home > News > DOING News> Feasibility analysis report of Waste plastic pyrolysis oil project (part 3)

Home > News > DOING News> Feasibility analysis report of Waste plastic pyrolysis oil project (part 3)

Feasibility analysis report of Waste plastic pyrolysis oil project (part 3)

DOING News / Date:January 24, 2018

waste plastic pyrolysis plant

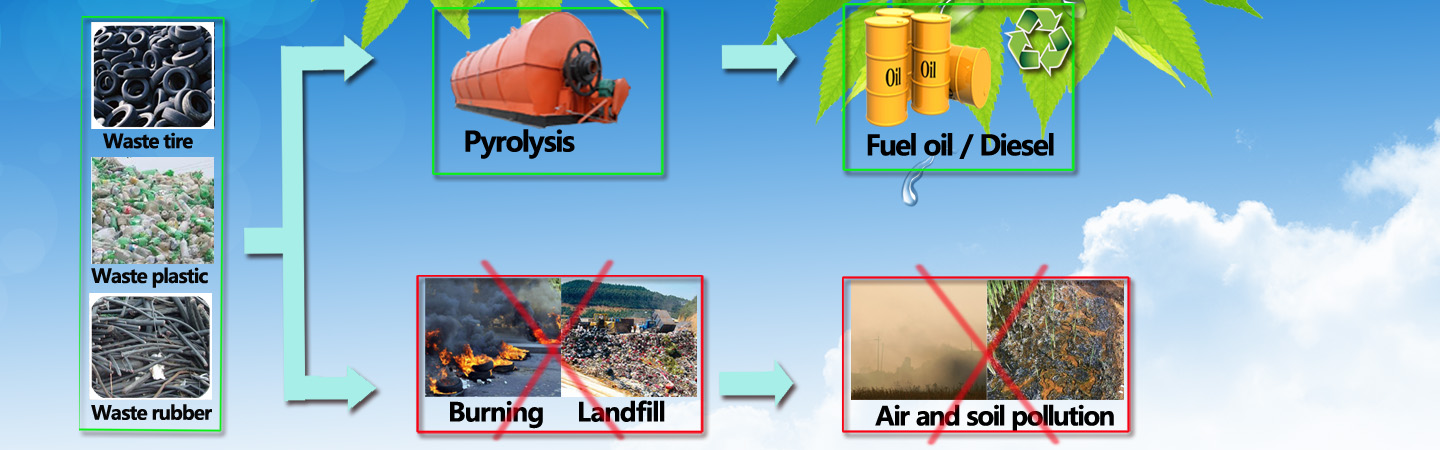

3. Working process

The technology and operation of DY series pyrolysis machine are easy and safe.The whole working process is in normal pressure,the raw material no need to be washed firstly,it can be put into the reactor for pyrolysis directly, and then heating, catalyzing,pyrolysis and cooling into fuel oil.

4. The raw material for pyrolysis

4.1 Industrial and house garbage plastic: thin film, diaphragm, film membrance, bottles, electrical appliances insulation, galvanic isolation materials, reticule, water pipes, oil tank, oil drum, drink bottle, calcium feeding-bottle, milk bottle, staple goods, necessity and so on.

With the upgrading of plastic packages, TVs, washing machine, refrigerator, computers, mobile phones, VCD,DVD and etc, the major environmental problem is caused by household electrical appliances. The quantity of the recycled waste plastic is produced more than 150 thousand tons every year. If adding the waste electronic communications equipments, the number will be 200 thousand tons. There are 1 million tons electronic electrical plastic accessories in the world, they are used widely in industry, digital information, transportation, aerospace and etc areas. Besides, they are upgrading very quickly. As such products are broken,it will be an important source of waste plastic.

4.2 Waste rubber tire and waste cable.

4.3 Waste oil( Waste engine oil,waste diesel oil ,waste oil sludge and so on)

4.4 Waste crude oil

5. Investment requirement and economic benefit analysis

5.1 Technical Parameter

| Technical parameter of DOING Pyrolysis Equipment | |||||

| Items | Contents | ||||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 | DY-1-12 |

| 2 | Raw material | tires/Plastic | tires/Plastic | tires/Plastic | tires/Plastic |

| 3 | 24-hour Capacity | 6 ton | 8 ton | 10 ton | 12ton |

| 4 | Marerial of Reactor | Q245R | Q245R | Q245R | Q245R |

| 5 | Thickness of Reactor | 14mm | 14mm | 16mm | 16mm |

| 6 | Total power | 17KW | 17KW | 25KW | 25KW |

| 7 | Cooling area of condenser | 40sqm | 40sqm | 65sqm | 65sqm |

| 8 | Noise dB(A) | ≤85 | ≤85 | ≤85 | ≤85 |

| 9 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 | 2800×6600 |

| 10 | Delivery time | 20days | 20days | 20days | 20days |

| 11 | Weight | 26T | 28T | 30T | 32T |

5.2 Investment requirement(take a DY-10 ton capacity pyrolysis for example)

| No. | Item | Cost of Per Batch |

| 1 | 10 tons of waste tires | 10T×800RMB/T=8,000RMB |

| 2 | 0.4 tons of coal | 0.4T×800RMB/T=320RMB |

| 3 | Water and electricity | 200×1.00RMB=200RMB |

| 4 | Workers | 4×100RMB=400RMB |

| 5 | Total Cost | 8,920RMB |

| NO. | Item | Income |

| 1 | Crude Oil | 10T×90%×4,500RMB=40,500RMB |

| 2 | Carbon Black | 10T×10%×520RMB=520RMB |

| 3 | Gross Profit | 41,020RMB |

| 4 | Daily Net Profit | 41,020RMB-8,920RMB=32,100RMB |

| 5 | Monthly Net Profit | 32,100RMB×25=802,500RMB |

| 6 | Yearly Net Profit | 802,500RMB×10=8,025,000RMB |

5.3 Investment recovery analysis

Take this DY-10 ton capacity machine for example,the machine can be finished installing in 30 days.All the investment can be recovered in two months.

6. Remarks

6.1 The price of raw material is decided by the local market, and the floating is not big.

6.2 Pls take the price of crude oil for reference. The data was reported in last year.

6.3 Our equipment and technology only establish the provincial or foreign agents,who can control the production line,sales or technology transfer in the local province.We don’t take part in their management.

6.4 If some factories want to be the province agent in the production line,we can lower the agent fee.

7. Conclusion

According the above analysis of the project: Making use of waste plastic pyrolysis oil project “converting the waste into treasure,benefit the nation and the people”,it is feasible on the technology. Low investment,enough raw material,short-term, and good prospects.So the waste plastic pyrolysis oil project is a very good choice to invest.

Request Information

Send your inquiry for further information