How does oil distillation plant work?

Waste Oil Distillation Plant / Date:May 6, 2017

Waste oil

Waste oil distillation plant

The waste oil mainly includes the recycled engine oil from cars, trucks, etc. and the pyrolysis oil which is produced by using the pyrolysis technology to process the waste materials, such as waste plastic, waste tyre, waster rubber, oil sludge as well as biomass.

How does oil distillation plant work?

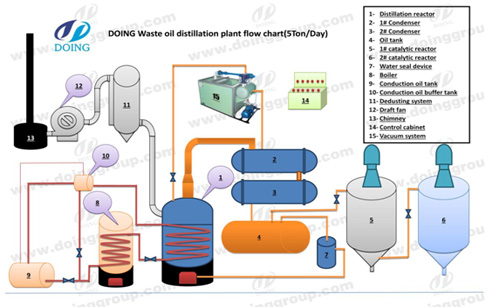

Waste oil distillation plant working process

First of all, put the crude oil in the fractional distillation plant for further process;

Secondly, heat crude oil in non-oxygen environment, which will start to boil and evaporate,

Thirdly, put those vapors through a cooling pipe and the vapors will condense to liquid , while some of the vapors with shorter hydrocarbon lengths will remain as a gas.

Fourthly, the exit of the cooling pipe is then going through a bubbler containing water to capture the last liquid forms of fuel and leave only gas that is then burned;

Finally, this kind of oil will be piped into deep purifying system with acidity and alkaline cleaning device as well as pressure filtering system.

Request Information

Send your inquiry for further information