How does tire/plastic pyrolysis work?

Waste Tire/Plastic Pyrolysis Plant / Date:March 5, 2021

Waste tire/plastic to fuel oil pyrolysis plant 3D image

Waste tire/plastic to fuel oil pyrolysis plant 3D image

Waste tire/plastic to fuel oil pyrolysis plant is the equipment that converts waste tires, plastics, rubber and other solid waste into pyrolysis oil, carbon black and hydrocarbon gas. Using waste tire/plastic to fuel oil pyrolysis plant to recycle these waste can reduce waste accumulation, which is good for human to protect the environment. Meanwhile, investors can get huge profits by selling its end products. But many people has doubt about pyrolysis technique. So let’s look at how waste tire/plastic pyrolysis works through waste tire/plastic to fuel oil pyrolysis plant now.

◆ Steps for waste tire/plastic to fuel oil pyrolysis plant

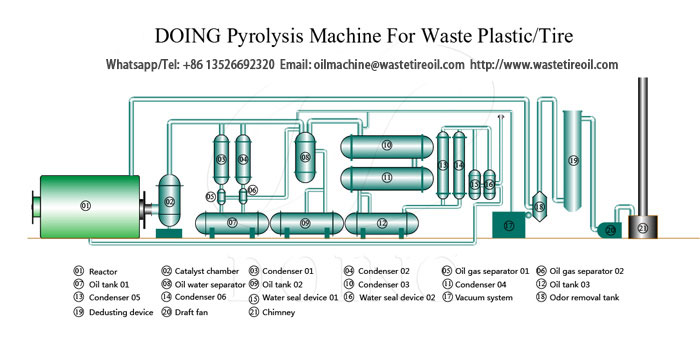

Waste tire/plastic to fuel oil pyrolysis plant workflow

Waste tire/plastic to fuel oil pyrolysis plant workflow

1.Feed raw materials (waste tire/plastic) into pyrolysis reactor by automatic feeding machine. The reactor is supposed to be left 1/3 space for rotating more smoothly. Then you must make sure the inlet of feeding machine closed tightly.

2.The pyrolysis reactor will be gently heated by burning the fuel material (coal, wood, natural gas, LPG or tire oil generated from waste tire/plastic to fuel oil pyrolysis plant). The oil gas will be released when the temperature reached 100℃(250-280℃ is the top output rate interval). Heavy oil gas separated by manifold is supposed to be liquefied to liquid directly and drop down into the heavy oil tank. The lighter gas will rise up to the oil condensers, be liquefied in to oil and stored in the oil tank. The non-condensable gas will go through desulfurization and dedusting system then be led to the furnace to heat pyrolysis reactor for recycling.

3.After all fuel oil is produced, the reactor should be cool down. Carbon black will be discharged automatically when the temperature falls down 40 degree. If the raw materials are waste tires, please take out steel wires from the reactor by hooks when the temperature is below 50 Celsius at least.

4.There possibly will be a little exhaust gas left, you can purify it by smoke cleaning system, so that it will reach emission standard.

5.Then you can start next batch.

If you want to get more information about waste tire/plastic to fuel oil pyrolysis plant, please contact us directly, we will reply you within 24 hours.

Request Information

Send your inquiry for further information