Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>Can we produce Refuse-derived Fuel(RDF) with pyrolysis plant?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>Can we produce Refuse-derived Fuel(RDF) with pyrolysis plant?

Can we produce Refuse-derived Fuel(RDF) with pyrolysis plant?

Waste Tire/Plastic Pyrolysis Plant / Date:January 3, 2023

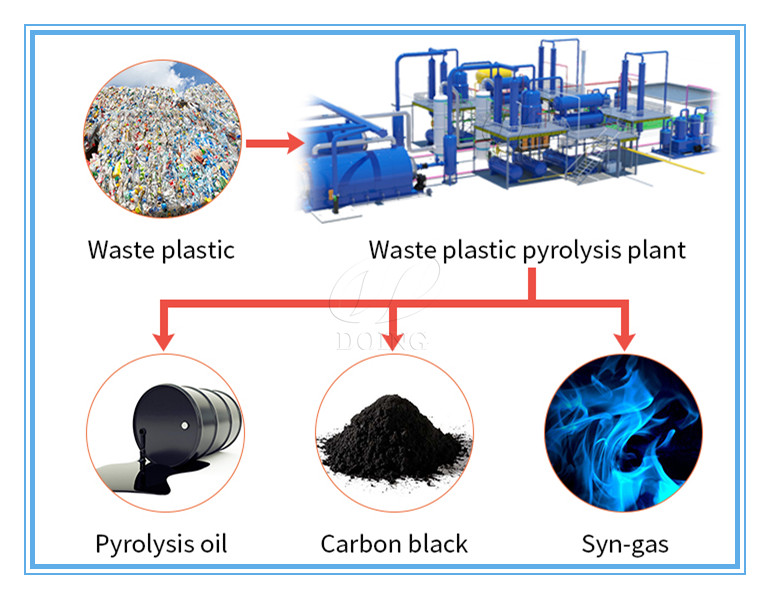

RDF is short for Refuse Derived Fuel, which is the final product of using pyrolysis plant to process waste tires, plastics, oil sludge and so on. It has the characteristics of high calorific value(10592.48Kcal/kg), stable combustion, easy transportation and exotic storage, etc. It is widely used in cement manufacturing, heating engineering and power generation engineering.

Then how do we produce Refuse-derived Fuel(RDF) with pyrolysis plant? Just take the mature technology of DOING Pyrolysis Plant for reference. The specific workflow of this Refuse-derived Fuel pyrolysis production line is as follows:

Waste plastics recycling pyrolysis plant

Waste plastics recycling pyrolysis plant

1. Feeding process.

First, use automatic feeder or manual to send waste (tires, plastics, sludge, etc.) into the reactor. After the completion of feeding, close the reactor door.

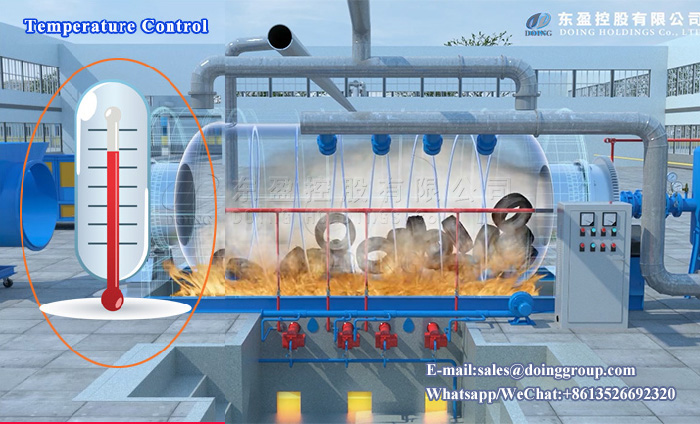

2. Preheating pyrolysis reactor.

Turn on the burner to preheat the reactor. After a period of preheating, exhaust gas will be produced. The exhaust spray gun is then turned on and the resulting exhaust gas is used to heat the reactor, saving more than half of the fuel.

Preheat the reactor

Preheat the reactor

3. Converting waste into oil.

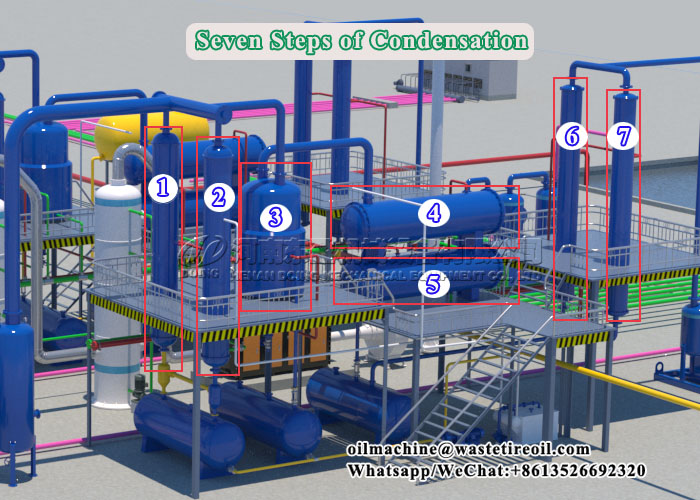

The oil gas in the waste raw materials will crack when it reaches a certain temperature. The cracked oil and gas will be cooled into liquid fuel(Refuse-derived Fuel) through the condensation system and collected in the oil tank.

4. Cooling down the reactor.

When the oil pyrolysis process is over, turn off all burners and turn on the cold air system to cool the reactor. Then the negative pressure system is opened to extract the remaining oil and gas in the reactor, and the remaining oil and gas are cooled into liquid fuel through the cooling system, which not only improves the oil yield, but also ensures safety and tasteless degree when the furnace door is opened.

The cooling system

The cooling system

The carbon black is then discharged and collected through the carbon black lift or air transport system, and the steel wire in the reactor is pumped out through the lift or wire drawing machine.

Now you should know how to get heating fuel from waste. This fuel has a great market value and is widely used in boiler plants, cement plants, steel plants, brick factories, glass factories, heavy oil power plants, heating and supply centers, etc. And the Refuse-derived Fuel obtained from pyrolysis plant can also be further refined into diesel fuel by waste oil distillation plant.

If you want to know more details about the waste to Refuse-derived Fuel pyrolysis plant, please feel free to contact DOING professional business manager.

Request Information

Send your inquiry for further information