Tyre /plastic pyrolysis plant produced tyre pyrolysis oil and plastic oil

The waste plastic used in pyrolysis process is needed to be sorted and cleaned. The Polyethylene (PE) and Polypropylene (PP) which are the main component of the plastic in municipal solid waste are used in the process in order to prevent the contamination of chlorine in the oil.

Tyre pyrolysis oil

The plastic pyrolysis oil used in this research is processed at 300-500 °C at atmospheric pressure for 3 hours. The product output consists of 60-80% pyrolysis oil, 5-10% residue and the rest is pyrolysis gas on weight basis. Pyrolysis is a complex series of chemical and thermal reactions to decompose or depolymerize organic material under oxygen -free conditions. The products of pyrolysis include oils, gases and char.

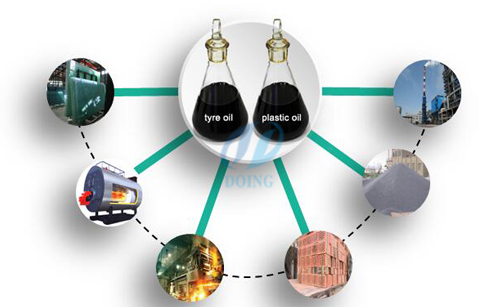

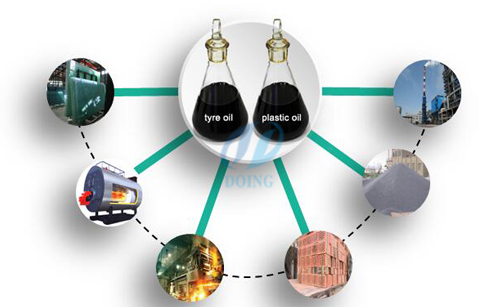

Tyre/plastic oil application

The pyrolysis oil products in this research are from tire and plastic which are dissimilar in physical properties and chemical properties. The appearance of the tire pyrolysis oil is thick-liquid and dark colour oil whereas the appearance of the plastic pyrolysis oil is like grease oil and dark colour oil at 30°C (room temperature). They all strong smell due to the high aromatic substance. As the comparison usage of this research is in diesel engine, the pyrolysis oil from process is a mixture of carbon composition which are C5-C20 in tire pyrolysis oil and C10-C30 in plastic pyrolysis oil 。