Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>How can old tires be converted to fuel oil by pyrolysis plant?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>How can old tires be converted to fuel oil by pyrolysis plant?

How can old tires be converted to fuel oil by pyrolysis plant?

Waste Tire/Plastic Pyrolysis Plant / Date:June 28, 2018

Old tire be converted to fuel oil by pyrolysis plant

by pyrolysis plant into

How can old tires be converted to fuel oil by pyrolysis plant?

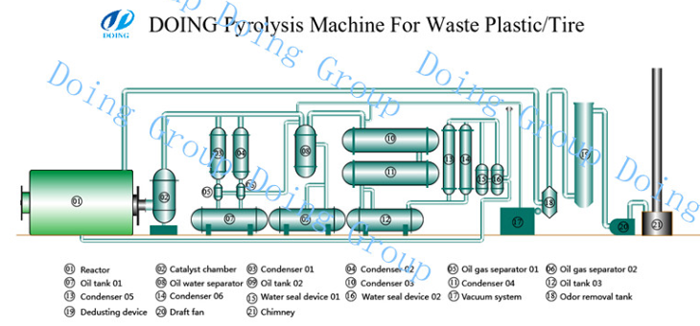

Tire pyrolysis plant working process

2. The waste tire is fed into the reactor and heated by an automatic feeder. As the temperature rises to 280-320 degrees, the oil and gas begin to crack.

3. The oil and gas cracked out first pass through the buffer tank. On the one hand, the speed of oil and gas is slowed down to make the condensation effect more uniform. On the other hand, the oil residue can be precipitated.

4. The buffered oil and gas enter the condensing system. In order to ensure that the oil and gas can be fully cooled and liquefied, the DoingGroup's condensing system is a three-stage condensing system. This condensing system is the most advanced in the oil industry and has the best performance. Condensing device. The highest oil yield can be guaranteed on the basis that the oil and gas in raw materials are evaporated and dried.

5. After the filter is clean and gas, it enters the water seal device. On the one hand, it is a safety device that can purify the exhaust gas produced during the combustion process and prevent backflow of the exhaust gas. It is called anti-tempering; on the other hand, customers can also Through the overflow of this equipment to determine the level of the oil rate.

6. After the water seal is filtered, it enters the negative pressure device. Like the water seal, the negative pressure device also plays a role in ensuring the safety of the device. In addition, the negative pressure device can also provide negative pressure, divert oil and gas, and improve the equipment output. Oil rate.

7. Spray three layers of water on the flue gas generated by combustion until the solid particles in the smoke are cleaned and discharged. It does not cause any pollution to the environment.

8. The carbon black produced during the combustion process will be automatically discharged through the sealed underground slag discharge system to avoid secondary pollution to the environment.

Tire oil further distillation machine

The above steps are only general steps for converting waste tires into fuel oil. For the entire process, we can also provide equipment, tire wire drawing machines, tire crushers, and other auxiliary equipment according to the needs of different customers. Of course, if you want to further refine the fuel oil and get cleaner non-standard diesel, we also have tire fuel oil distillation machine!!More information about how can old tires be converted to fuel oil by pyrolysis plant and equipment operation information please feel free to contact us!

Request Information

Send your inquiry for further information