How to recycling of tyre to oil ?

Waste Tire/Plastic Pyrolysis Plant / Date:April 25, 2018

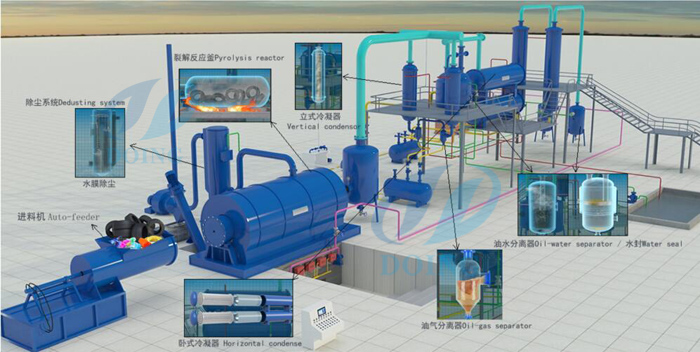

Tyre to oil recycling machine

Tyre to oil recycling machine working process

In the waste tyre pyrolysis process, the waste tyres will firstly be put into the reactor. Secondly, burn the fuel material (coal, wood, oil or natural gas) in the combustion system. The reactor will slowly heat, when the temperature reach around 120℃, it will produce oil gas.

Thirdly, oil gas will be processed and then go to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure will go back to combustion system to replace the fuel material to burn the reactor.

Tyre to oil recycling machine successful installed

Lastly, the released gas can achieve national emission standard through the dedusting system。

After the whole pyrolysis process of tyres is completed, the final products such as tyre oil, carbon black and steel wire can be sold directly or further processed into new products. Anyway, you will benefit a lot from them.

Fuel Oil (40% to 45%)

Tyre oil application

The main oil product produced by our recycling application is the fuel oil that is wide used for industrial and commercial purposes. The oil has 40% to 45% of the amount of recycled scrap tyres, which will be carried with licensed tanker trucks.

Request Information

Send your inquiry for further information