How to recycle oil sludge to get fuel oil?

Waste Tire/Plastic Pyrolysis Plant / Date:December 12, 2020

Oil sludge is a solid or liquid waste produced from oilfield production. It is a complex mixture of oil, water, and solids, which can cause serious environmental pollution, and contaminate soil and water. In order to treat oil sludge, it is necessary to separate the oil, water and solids, but the oil content cannot be separated out directly. Therefore, a reasonable and effective treatment method is needed to recycle and utilize the oil sludge and degrade the harmful components of the sludge in accordance with environmental emission standards. But how do we recycle it?

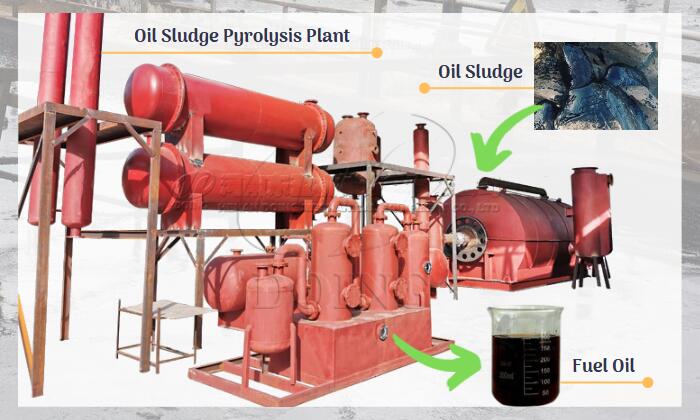

Doing oil sludge pyrolysis plant

Doing oil sludge pyrolysis plant

Today we will introduce an oil sludge pyrolysis technique, which is the thermal decomposition of materials in the absence of oxygen to break down the chemical bonds in molecules, and then turn large molecules into small molecules. The oil sludge pyrolysis plant produced by Henan Doing Environmental Protection Technology Co., Ltd is to separate oil, water and solids through thermal pyrolysis technique, and the whole process is environment friendly.

Let's take a look at how to recycle oil sludge to get fuel oil step by step.

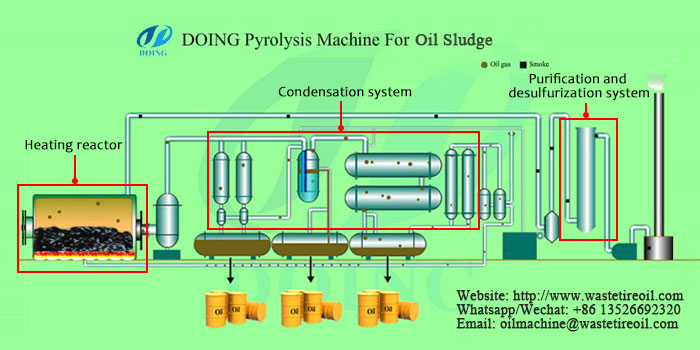

The process of DOING oil sludge pyrolysis plant

The process of DOING oil sludge pyrolysis plant

First, the oil sludge is continuously fed into the pyrolysis reactor through a conveyor, and the oil sludge is sealed in an oxygen-free environment.

Second, the pyrolysis reactor is rapidly heated to a higher reaction temperature by external heating of fuels such as coal, wood, oil, and natural gas. So that the large molecules are decomposed into small molecules of gasand a small amount of coke products. High-temperature oil gas, water vapor and solid products are obtained.

Third, the high-temperature oil gas and water vapor pass through oil-water separator and are cooled by the condensation system to obtain liquid fuel oil and a small amount of combustible gas.

Last, the final product, liquid fuel oil, is pumped to the fuel tank. The combustible gas is purified and recycled as fuel for heating the pyrolysis reactor. The slag produced after pyrolysis will not cause secondary pollution to the environment, can be treated as solid waste, the flue gas produced in the production process will be cleaned by flue gas purification and desulfurization system to meet the environmental protection standards.

Oil sludge pyrolysis plant is a good way to recycle oil sludge to get fuel oil. It not only solves the environmental pollution of oil sludge, but also generates renewable energy, which will bring considerable benefits to customers. Do you need such a machine? Welcome to place your order, Doing engineers will surely provide you with the most suitable equipment to meet your production needs.

Request Information

Send your inquiry for further information