Pyrolysis of waste plastics into fuels ?

Waste Tire/Plastic Pyrolysis Plant / Date:May 6, 2017

Waste plastic

Pyrolysis plastic to fuel oil

While the weighted average life (time to disposal) of all plastic is eight years, more than 40% of plastics have a life-span of less than one month, meaning that significant volumes of waste are generated annually. Post-consumer plastics make up a major portion of municipal solid waste and appear in waste streams from agriculture, distribution and packaging, construction and demolition, automotive, electrical and electronic applications. The fraction of plastic in municipal solid waste comprises 60% polyolefins (POs) such as high density polyethylene, low density polyethylene and polypropylene, which is desirable from a PTL standpoint since they are the most suitable candidates for quality plastic-to-liquid fuel productionPlastic’s durability is also its worst enemy, as plastic in landfills can take several hundred years to degrade. One of the characteristics is that all plastics can theoretically be recycled, either into other materials, such as polyethylene terephthalate (PET) bottles which end up as pillow stuffing, or others which are returned to the resin state for re-use as other plastics.

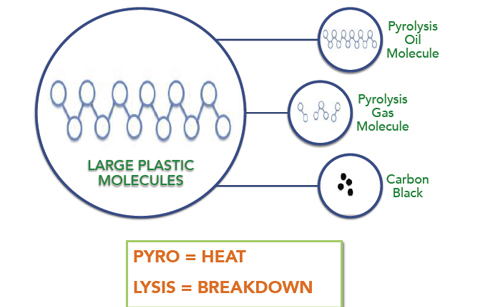

Pyrolysis

Pyrolysis

Recently, the technology has matured to the point where commercial plants are now available. Pyrolysis recycling of mixed waste plastics into generator and transportation fuels is seen as the answer for recovering value from unwashed, mixed plastics and achieving their desired diversion from landfill.

Pyrolysis waste plastic to fuel oil machine

Request Information

Send your inquiry for further information