Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What is pyrolysis technology of waste plastic and tire?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What is pyrolysis technology of waste plastic and tire?

What is pyrolysis technology of waste plastic and tire?

Waste Tire/Plastic Pyrolysis Plant / Date:April 1, 2017

Pyrolysis

Plastic and tire pyrolysis plant

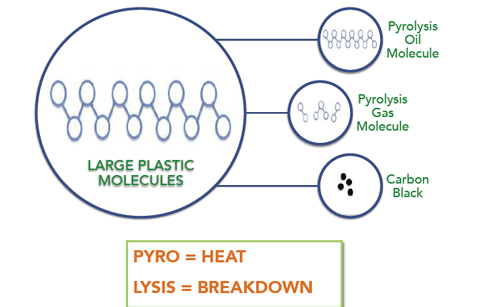

Pyro = heat, lysis = breakdown into parts. Pyrolysis is chemical reaction in which large molecules are broken down into smaller molecules. Simplest example of pyrolysis is cooking in which complex food molecules are broken down into smaller & easily digestible molecules.

Waste plastic and tire pyrolysis

Waste plastic and tire are long chain molecules or polymer hydrocarbons. Pyrolysis technology is the industrial process of breaking down large molecules of plastic/tire into smaller molecules of oil, gas and carbon black. Pyrolysis of waste plastic or tire takes place in absence of oxygen, at about 350-550 degree C and reaction time is about 15-45 minutes.

Plastic pyrolysis or tire pyrolysis is: the process of converting waste plastic/tires into industrial fuels like Pyrolysis Oil, Carbon Black and Hydrocarbon Gas. Plastic and tire pyrolysis takes place in pyrolysis reactor. Pyrolysis reactor creates following process conditions to carry out plastic or tire pyrolysis:

Plastic and tire pyrolysis involves subjecting plastic and tire to high temperature of 400 to 450 degree Celsius, in absence of oxygen. In case of oxygen is present plastic will start burning. During pyrolysis plastic and tire breaks down into smaller molecules of pyrolysis oil, pyrolysis gas and carbon black. Like plastic and tire, pyrolysis end products are also hydrocarbons. Pyrolysis is great way of recycling waste plastics and tires. Given below are benefits of waste plastic and tire pyrolysis.

Request Information

Send your inquiry for further information