Plastic to oil recycling process ?

Waste Tire/Plastic Pyrolysis Plant / Date:February 6, 2018

Plastic to oil

The experts believe that plastic products can significantly reduce energy consumption and greenhouse gas emissions, particularly in the use of plastic insulation, food packaging and renewable energy production process, significant benefits can be obtained. The study data shows that in Europe, the application is 5 to 9 times higher than the income of plastics and plastic products recycling process emissions; to 2020, the revenue of using plastic will be 9 to 15 times higher than the production of plastics and waste plastic to bring emissions.

Plastic to oil recycling process machine

Plastic to oil recycling process ?

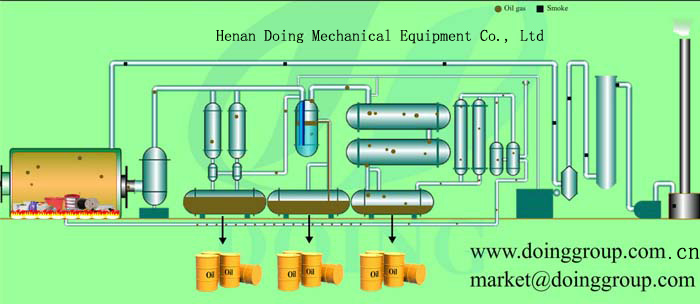

Plastic to oil recycling process

Pretreated plastics will be conveyed to the moving horizontal pyrolysis reactor through feeder system, it starts to pyrolysis and oil gas will be generated when temperature up to 500 degrees. Then the oil gas will be cooling down by spray cooling system, it would be liquefied, go into the oil tank. And at the same time, some uncondensed gas come into hot air circulation heating system by secondary fire retardant damper, it will be recycled for heating reactor as gas material. Exhaust gas go to the strong spray dedusting system for removing pollution, then let environmental gas go to the air. The pyrolysis slag emissions and recycled through second sealed discharging system.

Request Information

Send your inquiry for further information