How to maintenance waste tire pyrolysis plant?

Waste Tire/Plastic Pyrolysis Plant / Date:July 23, 2018

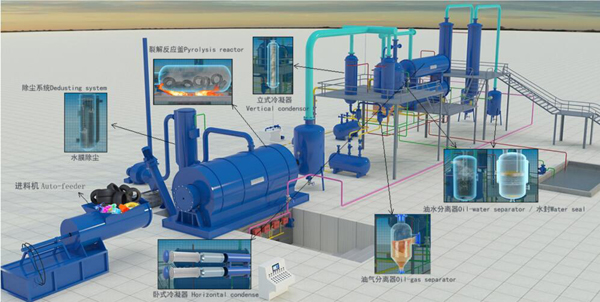

DOIGN waste tire pyrolysis plant

DOING waste tire pyrolysis plant working process

Due to the continuous increase in international crude oil prices and the inconsistency of domestic refined oil prices, domestic old type pyrolysis plant companies have suffered huge losses in the past two years. In order to pursue efficiency, enterprises are more inclined to purchase heavy, high-sulfur and high-acid crude oil with relatively low purchasing prices. The failure of many devices that do not have new environmentally friendly pyrolysis plant is more obvious.

DOING company new environmentally friendly waste tire pyrolysis plant is environmentally friendly and pollution-free, no black smoke and no smell. The reactor of DOING company's new environmentally friendly pyrolysis plant is not liquefiable during the catalytic catalytic treatment of waste rubber and plastics. The direct combustion of exhaust gas C1 and C4 alkanes is dangerous. Before burning these as fuel, it is first safely filtered, then sealed by the first liquid, and then passed through the second safety device gas nozzle, so that it can completely achieve safe production.

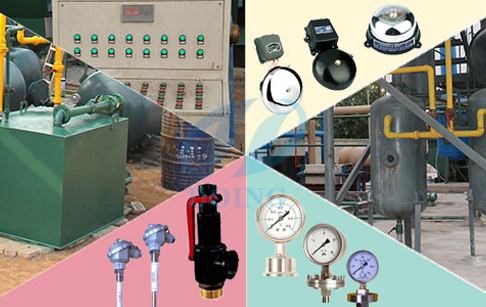

DOING waste tire pyrolysis plant safety device

In the safe production of DOING company's new environmentally friendly pyrolysis plant, it is equipped with safety devices such as pressure gauges, thermometers and automatic alarm devices. Others such as: condensing system, exhaust gas purification and other systems, the use of safety devices, meticulous to all parts; automatic alarm, automatic risk.

DOING company's waste tire pyrolysis plant is not only of high quality, but also easy to maintain in the later stage. Save a lot of precious time for you, it is the best choice for your investment!

Request Information

Send your inquiry for further information