Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>Legal procedures for buliding a waste tire pyrolysis plant factory

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>Legal procedures for buliding a waste tire pyrolysis plant factory

Legal procedures for buliding a waste tire pyrolysis plant factory

Waste Tire/Plastic Pyrolysis Plant / Date:July 17, 2018

Nowadays, due to the country's emphasis on environmental protection, and some environmental regulations introduced this year, the old, non-environmental pyrolysis plant was forced to close. Under the guidance of national policies, more and more people want to operate the waste tire pyrolysis plant through formal channels. So what are the legal procedures for building a waste tire pyrolysis plant factory?

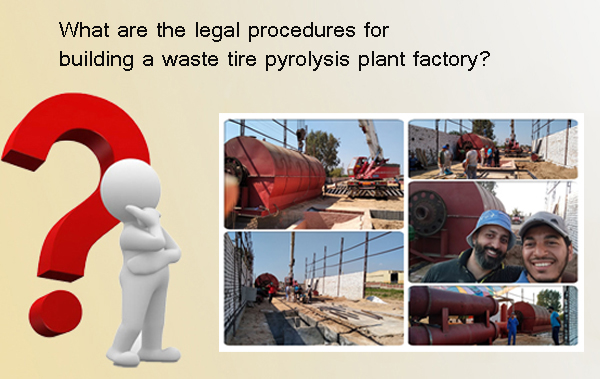

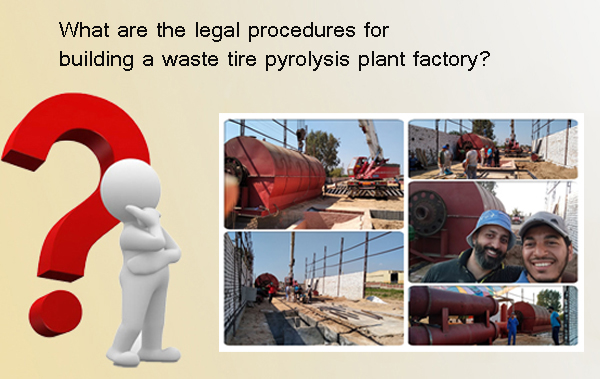

Our Egypt customer waste tire pyrolysis plant installation spot

The legal procedures for building a waste tire pyrolysis plant factory, the following points should to be considered:

(1) Environmental issues. To ensure the environment of the factory and the surrounding environment, the air, water quality, soil and human health of the factory and its surroundings will not be affected by a series of effects. Waste tire refineries generate some noise during operation, so you should stay away from residential areas when you use used tire refineries.

Land hardening

(2) Land hardening. To ensure the hardening of the factory land. Under normal circumstances, waste tires will produce waste water, waste oil and other products in the process of oil pyrolysis. If the land is soft, it will cause leakage of waste. Try to reduce the amount of waste to a minimum.

(3) Reasonable use of waste. Part of the waste, such as asphalt, is produced during the production of waste tire pyrolysis plant. To ensure the rational use of waste, dumping at will not only affect the environment, but also will not obtain certain economic benefits. It is closely related to the process technology used in the legal procedures for handling used tire refineries.

(4) To handle the legal procedures of the used tire pyrolysis plant, it is necessary to comply with the following requirements, “three wastes” emissions, emission concentrations, noise conditions, comprehensive utilization of solid waste, and pollution control effects. The legal procedures for the recycling of used tires are successful, and have the most direct connection with the waste tire pyrolysis plant. Therefore, in addition to the above factors to be considered, it is also very important to choose a qualified equipment manufacturer. DOING's waste tire pyrolysis plant is designed in strict accordance with European and American environmental assessment standards to ensure that your environmental emissions can meet the requirements of local environmental protection departments.

DOING waste tire pyrolysis plant

Dealing with waste tire pyrolysis plant is an investment that conforms to the trend of the times. Although the country has stricter regulations on environmental protection, it shows that this is a transition period of the pyrolysis plant industry and the best period for your investment. As long as we consider it well and choose the right equipment supplier, it is not a problem to get local environmental approval procedures and legalize and scale operations. At present, many of the customers we have coperated with have invested in our equipment and have successfully obtained local environmental assessment procedures. Do you want to know more about the legal procedures for buliding a waste tire pyrolysis plant factory? Welcome online consultation!

Our Egypt customer waste tire pyrolysis plant installation spot

The legal procedures for building a waste tire pyrolysis plant factory, the following points should to be considered:

(1) Environmental issues. To ensure the environment of the factory and the surrounding environment, the air, water quality, soil and human health of the factory and its surroundings will not be affected by a series of effects. Waste tire refineries generate some noise during operation, so you should stay away from residential areas when you use used tire refineries.

Land hardening

(3) Reasonable use of waste. Part of the waste, such as asphalt, is produced during the production of waste tire pyrolysis plant. To ensure the rational use of waste, dumping at will not only affect the environment, but also will not obtain certain economic benefits. It is closely related to the process technology used in the legal procedures for handling used tire refineries.

(4) To handle the legal procedures of the used tire pyrolysis plant, it is necessary to comply with the following requirements, “three wastes” emissions, emission concentrations, noise conditions, comprehensive utilization of solid waste, and pollution control effects. The legal procedures for the recycling of used tires are successful, and have the most direct connection with the waste tire pyrolysis plant. Therefore, in addition to the above factors to be considered, it is also very important to choose a qualified equipment manufacturer. DOING's waste tire pyrolysis plant is designed in strict accordance with European and American environmental assessment standards to ensure that your environmental emissions can meet the requirements of local environmental protection departments.

DOING waste tire pyrolysis plant

Request Information

Send your inquiry for further information