Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>Why we developed the continuous waste tyre pyrolysis plant?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>Why we developed the continuous waste tyre pyrolysis plant?

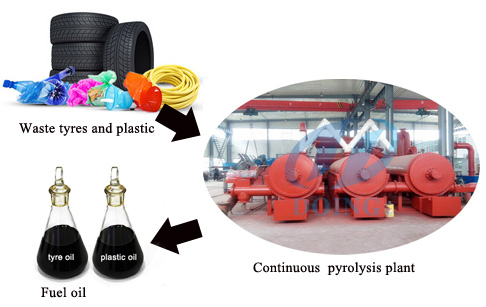

Why we developed the continuous waste tyre pyrolysis plant?

Waste Tire/Plastic Pyrolysis Plant / Date:April 27, 2017

Continuous waste tyre pyrolysis plant

First of all ,lots of company produced batch pyrolysis plant ,By this type of pyrolysis plant, workers should fill the raw material, for example, the waste tyre, plastic with a batch of raw material and take the process, and then after cooling down and removal of the carbon, the next process will happen. Batch pyrolysis plant is able to process 10 tons raw material one day. It needs feeding time for one and a half hour, processing time for eight to nine hours, cooling time for five to six hour, and slagging out time for two hours. In this process, the steel wire should be pulled out by people. It is more traditional, so it is cheap enough for people who haven’t prepared enough fund for this project.

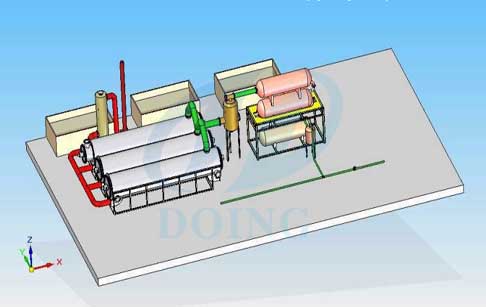

3 D picture of continuous waste tyre pyrolysis plant

Request Information

Send your inquiry for further information