How scrap cable stripping machine works?

Auxiliary Equipment / Date:July 12, 2016

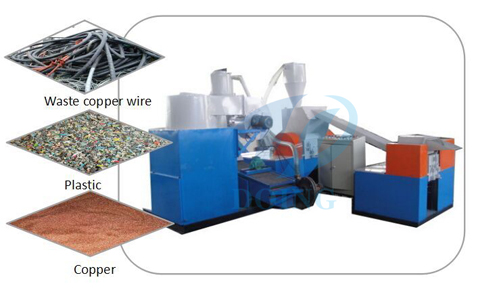

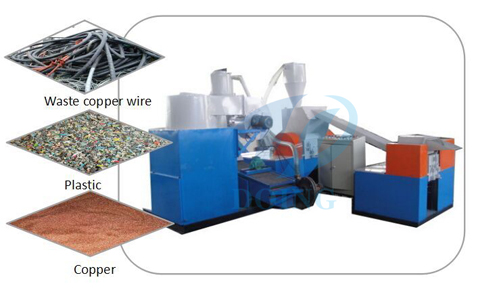

Scrap cable stripping machine of Doing is environmentally friendly machine,which can cush and process all kinds of waste copper wire and separated copper and plastic.

Scrap cable striping machine

So ,the scrap cable stripping machine works?

2. Magnetic conveyor; to convey the scrap copper wire that being cut in previous cutter to the No. 2 crushing machine.

3. The second crushing machine; this machine separates the plastic and metal totally. At the bottom, there is installed sieve which can control different sizes materials.

4.Air blower; transporting the small particles that from No. 2 crushing machine to grading machine by using wind and wind pressure.

5.Grading machine; it is the core of the machine. It separates the copper and plastic skin totally. Although it is with complex structure, it has the features of convenient operation.

6.Bag dust-separator; It collects the dust from grading machine through dust blower. The upper part has 12 filter bags.

7.Air rock; it is in the bottom of the dust collector. It is the air rock that timing operation in order to discharge the dust.

8.Screw conveyor; conveying the dust that from the dust collector to the external of the whole equipment.

9.Control cabinet. It controls all the scrap cable stripping machine in the whole equipment. It has the functions of emergency stop and timer.

Scrap cable striping machine

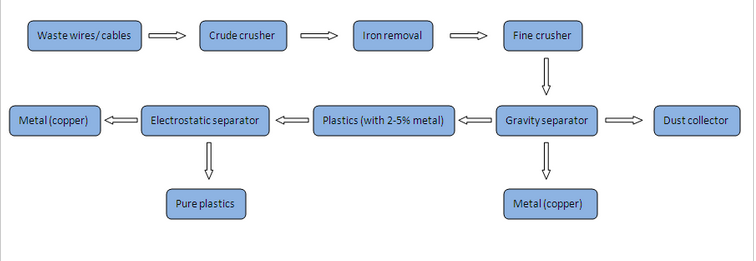

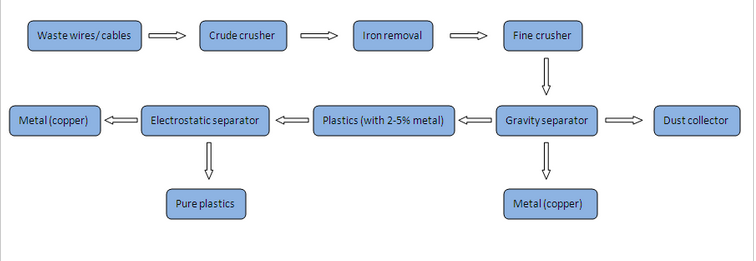

Flow chart of scrap cable stripping machine

1.The first cutting machine; the workers put the scrap cable wire into the scrap cable stripping machine works cutting machine;2. Magnetic conveyor; to convey the scrap copper wire that being cut in previous cutter to the No. 2 crushing machine.

3. The second crushing machine; this machine separates the plastic and metal totally. At the bottom, there is installed sieve which can control different sizes materials.

4.Air blower; transporting the small particles that from No. 2 crushing machine to grading machine by using wind and wind pressure.

5.Grading machine; it is the core of the machine. It separates the copper and plastic skin totally. Although it is with complex structure, it has the features of convenient operation.

6.Bag dust-separator; It collects the dust from grading machine through dust blower. The upper part has 12 filter bags.

7.Air rock; it is in the bottom of the dust collector. It is the air rock that timing operation in order to discharge the dust.

8.Screw conveyor; conveying the dust that from the dust collector to the external of the whole equipment.

9.Control cabinet. It controls all the scrap cable stripping machine in the whole equipment. It has the functions of emergency stop and timer.

Request Information

Send your inquiry for further information