Home > Project Case > In Asia>5 sets of DY-15Ton semi-continuous plastic pyrolysis plants installed in China

Home > Project Case > In Asia>5 sets of DY-15Ton semi-continuous plastic pyrolysis plants installed in China

5 sets of DY-15Ton semi-continuous plastic pyrolysis plants installed in China

In Asia / Date:April 9, 2024

In March 2024, Henan Doing Company's five sets of DY-15Ton semi-continuous plastic pyrolysis plants were installed in Gansu Province, China, and were successfully put into operation!

Semi-continuous plastic pyrolysis plants installed in China

Semi-continuous plastic pyrolysis plants installed in China

These five sets of DY-15Ton semi-continuous plastic pyrolysis plants can process a wide range of waste plastics, such as PP/PE/PS/ABS, paper mill waste materials, plastic sheets, vehicle bumpers, plastic domestic waste, plastic cable sheaths, etc.

This waste plastic oil pyrolysis project is our second cooperation with our Chinese customer. Prior to this, we have assisted this customer in building a waste plastic pyrolysis project with an annual processing capacity of 30,000 tons in Inner Mongolia, China. Both waste plastic pyrolysis projects use the same process and equipment configuration scheme, namely 5 sets of DY-15Ton semi-continuous plastic pyrolysis plants. Henan Doing Company participated in the entire project construction process, and we are very honored to receive the trust and recognition from our customers.

Semi-continuous waste plastic to oil pyrolysis projet picture

Semi-continuous waste plastic to oil pyrolysis projet picture

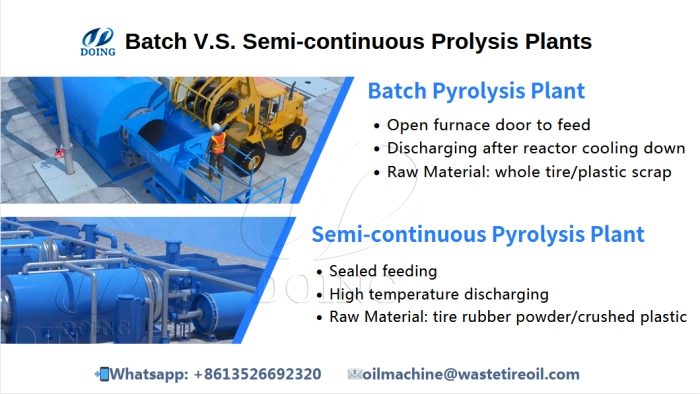

The reactor dimensions and processing capacity of semi-continuous waste plastic pyrolysis plant are the same as those of batch pyrolysis plant. The differences lie in the improvement of the plastic feeding way and carbon black discharging way. The semi-continuous plastic pyrolysis plant uses a screw conveyor to convey the crushed waste plastic pieces, saving labor and shortening the time required for feeding. Carbon black discharge adopts water-cooled spiral slag discharge, which can achieve high temperature discharge of 200°C. Batch pyrolysis plant can only be discharged when the furnace drops below 50°C. Therefore, the semi-continuous pyrolysis plant effectively improves the production efficiency of pyrolysis waste plastic into oil. Under the same specifications and dimensions, batch pyrolysis plant can process one furnace of waste plastic per day, while semi-continuous pyrolysis plant can achieve the production efficiency of three furnaces in two days.

Semi-continuous pyrolysis plant V.S. Bacth pyrolysis plant

Semi-continuous pyrolysis plant V.S. Bacth pyrolysis plant

After the semi-continuous plastic pyrolysis project is put into operation, it will not only contribute to sustainable utilization of waste plastics in Gansu Province, China, but also help to produce valuable alternative fuel resources and create more profits.

Whether you want to start a small or large waste to fuel pyrolysis related business, welcome to contact Henan Doing Company. We will provide you with a one-stop chain of comprehensive services to assist with the overall planning and implementation of your pyrolysis plant project!

Request Information

Send your inquiry for further information