1.Compact structure, reasonable layout, stable performance and low noise.

2. Uniform feed full production line adopts PLC control, coordinated operation.

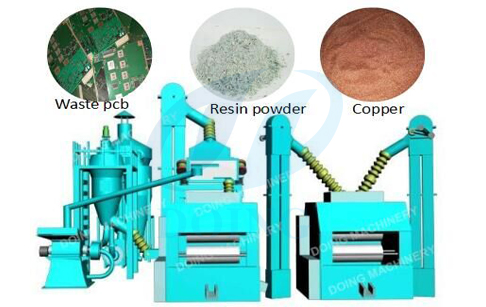

3. three-stage crushing, handling capacity per hour 1200kg.

Crushing chamber with circulating water temperature control and noise reduction.

4.full production line using negative pressure feeding effectively reduce dust overflow.Back feeding system so crushed more efficient.

5. Airflow separation equipment sorting rate of 97 to 99%.

6. Pulse dust removal equipment efficiency up to 99.99%.

7. high voltage electrostatic sorter sorting the finer more efficient, effective control of non-ferrous metal loss.

8. Complete production line of high disposal bridge and guardrail convenient access real-time monitoring and maintenance of the equipment.

9. waste and scrap the device settings hydraulic system to facilitate the replacement of wearing parts, improve