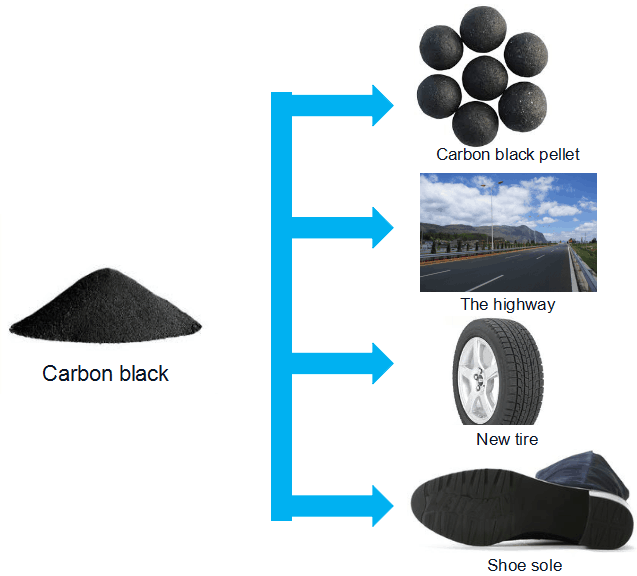

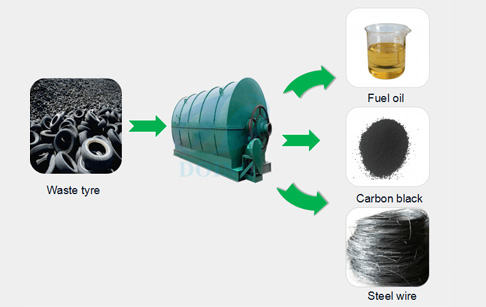

Doing group is one the leading Waste tyre recycling process machine cost to fuel oil manufacturer and Exporter from China. Doing group is pioneer name in the field of Waste tyre recycling waste tyre recycling process plant in all over world. Doing believe in innovative technology and we apply the same concept in our aste tyre recycling process machine cost. These aste tyre recycling process machine cost can be most cost-effective in the world. Doing group waste tyre recycling process machine cost manufacturer cost can be availed at leading market price. In this plant get valuable output Fuel oil, Carbon Black, Steel Wire scrap, Gas.

| Technical parameter of Waste tyre recycling process machine cost | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste tyre recycling process machine cost | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |